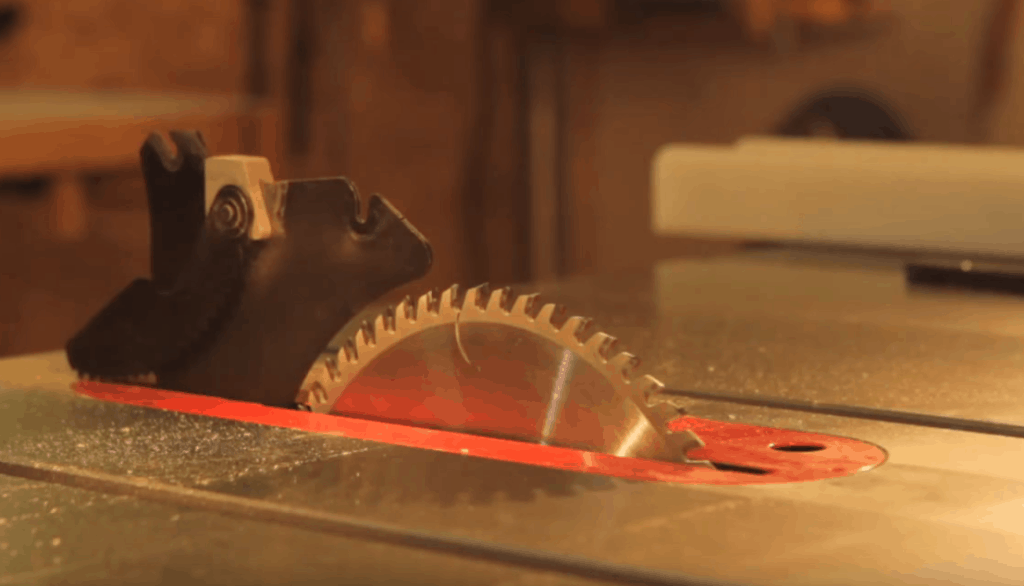

Welcome! If you’re looking to slice through your projects with precision, a solid table saw is your best buddy. From quick rip cuts to complex joinery, having the right table saw makes a world of difference. We’ve gathered the technical details, honest reviews, head-to-head comparisons, and loads more to help you pick the table saw that’s just right for your workshop. Flip through our articles and get all the info you need to buy with confidence.

Table Saw Guide

Let us help you get the best results from your table saws. This guide will help you make precise cuts, use your blade guards and push stick for more safety, and show you the range of wood cuts and projects your tool can help with. We’ve been customers, too, so we’ll show you what to look for in a top-quality table saw.

Read the Table Saw Guide

Tool Details

If you’ve already found a table saw and just want to know a bit more about it, this is where to go. We gather all the tech specs for power tools from the major brands so you can see measurements, power, accessories, and more before you head to the shop.

Find Your Table Saw Specifications

Tool Reviews

Straight talk from folks who’ve put these saws through their paces. Our reviews dig into the latest table saws hitting the shelves, breaking down what’s hot and what’s not to save you the guesswork. We’ll help you work out if the tool is worth the cost.

Read Our Table Saw Reviews

Tool Comparisons

Sometimes it’s a close call between a couple of saws. We lay them out side by side, comparing what matters to you: how they perform, what they’ll set you back, and where they stand out or fall short. You can expect us to show you their best features as well as their worst points.

Compare Table Saws

Best Tools

After all is said and done, you want to know which saws take the cake. We’ve lined up our top picks for the best table saws based on performance, value, and user satisfaction. We’re not loyal to any brand – we just want you to be equipped with the best tools you can afford.

Discover the Best Table Saws

How-to Guides and Projects

Got your table saw and ready to cut? Awesome. You might already have a project in mind. If you don’t have one (or your spouse hasn’t told you yet!), check out these guides and project ideas to spark your creativity and get the most out of your new tool.

Find Your Next DIY Project

If you’re looking for a different tool – because who needs just one? – then go back to our Woodworking Tools page for more info about all kinds of tools.