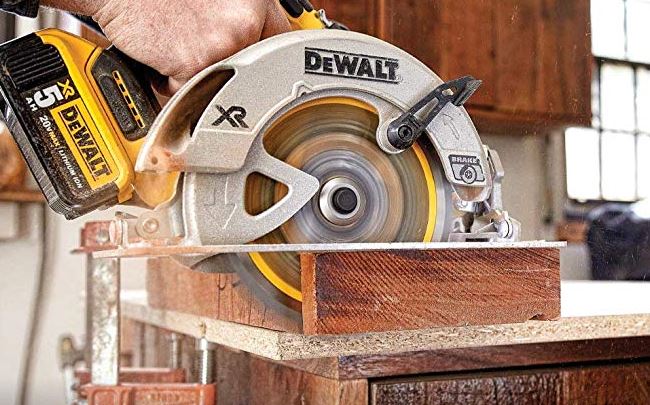

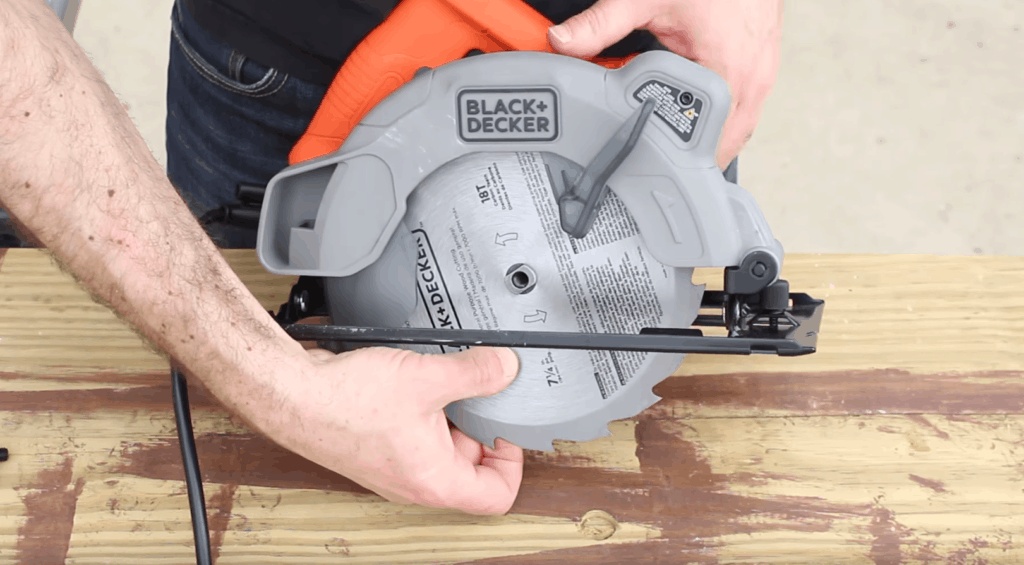

Got a project in mind? A circular saw can help. Whether it’s cutting a piece of wood straight or at an angle, these saws do the job well. If you’re trying to choose between a corded circular saw or the latest battery model, you’re in the right place. We’ve got the lowdown on what makes a good saw great.

Circular Saw Guide

Want to use a circular saw like a pro? Check out this guide. We talk about how to pick the right saw for your work, the difference between corded circular saws and cordless circular saws, and why things like a good blade guard and a laser guide matter. It’s all about making your job easier and safer.

Read the Circular Saw Guide

Tool Details

Need the specs on circular saws? This is where you’ll find them. Get the scoop on different power tools, what they can do, and what to look for. We cover everything from battery life, electric brake, blade speed, blade size, to how much power you need to cut through different materials. Find out which saws make the cut.

Find Your Circular Saw Specifications

Tool Reviews

Hear from people who’ve actually used these saws. We look at a bunch of circular saws and tell you what we think. It’s all about making straight cuts, keeping the saw blade safe, and accurate cutting. Learn from our experiences about which saws work best for tasks like cutting plywood sheets, making freehand cuts, or slicing through laminate flooring.

Read Our Circular Saw Reviews

Tool Comparisons

Can’t decide between two saws? We compare them for you. Find out how they stack up in terms of power, ease of use, and those extra features that make a difference, like how fast the electric brake stops or if there’s a light to show you the cut line. We’ll also look at how easy it is to find replacement circular saw blades and your options for keeping a great cutting edge.

Compare Circular Saws

Best Tools

Here are our top picks for the best circular saws. Whether you need something heavy-duty for a construction site or something lighter for DIY home projects, we’ve got recommendations for the best saws out there. We’ll also show you options, such as miter saws and a table saw, that might be a smarter choice for certain project.

Discover the Best Circular Saws

How-to Guides and Projects

Ready to start using your circular saw? We’ve got tips and project ideas. Learn how to make all kinds of cuts, pick the right blade for the job, and even tackle some creative projects with your circular saw. We’ll show you projects for sheet material, thicker material like natural lumber, and other popular circular saw projects you can get started on.

Find Your Next DIY Project

If you’re looking for a different tool – because who needs just one? – then go back to our Woodworking Tools page for more info about all kinds of tools.