HardieBacker is the #1 selling cement-based backer board on the market. With its lifetime warranty and MoldBlock TM technology, it’s the absolute standard nowadays for construction and home improvement projects in ‘wet’ areas such as kitchens and bathrooms.

It’s offered in either 3x5 or 4x8’ sheets, in two different thicknesses - HardieBacker 500 (0.42”), and HardieBacker 1/4”. The 1/4” is used primarily as countertop underlayment, while the 500 is used under floors and behind walls. Both work as excellent tile underlayment, while the smooth-surfaced 500 is suitable for painting or wallpapering and can be used as a replacement for drywall.

HardieBacker board is composed of 90% Portland cement and ground sand, and has no paper facing (which is a food source for mildew). Also, unlike other backing board materials, it contains no asbestos, formaldehyde, or gypsum.

Here is a good PDF specifications chart comparing HardieBacker with other backing board materials currently on the market.

Cutting and working with HardieBacker board is relatively simple with the right tools – even when difficult angled or circular cuts are needed to fit around corners, faucets, pipes, or showerheads. In fact, the 1/4” board is manufactured with EZ Grid TM perforated grooves, which make smooth cuts and ultra-detailed work much more achievable for the amateur.

Cutting: Tools, Tips, and Techniques

For long, straight sections, the recommended method for cutting HardieBacker board (or any cement backing board for that matter) is the score and snap method. While a specialized carbide-tipped scoring knife will make the job easier, a general utility knife will work as well.

To score the board, simply lay it flat on the ground, mark out your line with a straight edge, and follow the line while applying firm pressure with the scoring knife. Once the score is made, use your body weight to hold the board down, then snap the scored part upwards to break it off.

For circles, curves, and small angles, the score and punch method is effective. Mark and score the circle, then score a few cross-sections of the area like you’re slicing a pizza. Next, using a hammer, start in the center of the circle and simply punch out the scored section.

You can do the same thing for squares, angles, and corners; simply mark and score the desired area, score cross sections, and break away the area with a hammer.

Here is a good video example of how to properly execute this technique:

Drilling holes along your desired line with a masonry bit will also work, but this is a longer process and doesn’t produce as clean a cut as scoring.

Cutting HardieBacker Board with Power Tools

The score and snap method is really the only option for cutting HardieBacker board if you’re working indoors.

Power tools can certainly be used as well, as long as you’re in a well-ventilated, outdoor area. The silica dust that cement board gives off when cut with a saw is not something you want floating around the inside of your home.

If you do use one of the following power tools, wear goggles and respiratory protection – even if you’re outside.

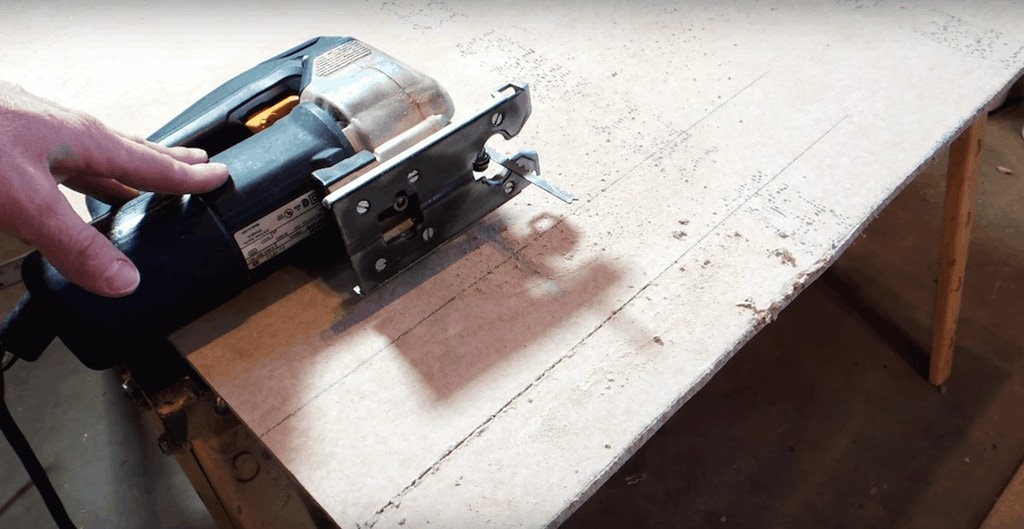

For long, straight cuts, a circular or jigsaw will work well with the proper blade. For the easiest, cleanest cut possible, you’ll want a carbide-tipped blade with as few teeth as possible. The more teeth on the saw blade, the more dust will be produced, and the rougher the cut will be. This 4-tooth HardieBlade from Diablo is actually specifically designed for cutting cement board. This less expensive, 6-tooth blade will also work well.

The same applies for jigsaws; use a coarse, carbide or diamond-grit blade and move slowly for the cleanest cut. Be prepared to change blades frequently though, as you’ll go through a lot. A jigsaw might be a good option if you have a large hole or square to cut out.

An angle grinder with a diamond-impregnated cut-off wheel can also be used, but this would produce lots of dust and would be an absolute nightmare trying to maintain a straight line.

Another option, if money is no concern or if you’re planning on cutting a lot of cement board, is a pair of electric cement shears like these from Makita. The cut produced is excellent, but with a price tag north of $200, practicality is more or less thrown out the window.

All in all, there are a range of options to choose from when it comes to cutting HardieBacker cement board. Just take your time, and choose your tool depending on the cut(s) you need.

Lastly, if using power tools, remember to work outdoors and always wear protective gear.